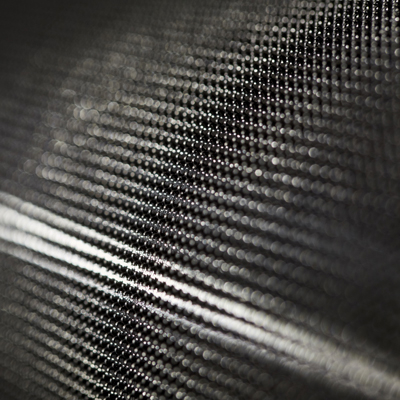

For more than 45 years, the CORDURA® brand has been recognised as a fabric brand of choice for products where robustness counts. The brand's DNA is based on pushing the boundaries of fabric robustness, offering an optimal strength-to-weight ratio and excellent abrasion, tear and wear resistance. CORDURA® nylon fabrics are engineered for durable and long-lasting performance.Cordura has become synonymous with rugged polyamide and nylon blend fabrics.

The patch is always delivered with black velcro as standard. If no Velcro is desired, please let us know before payment. Then your patch will be made without velcro for sewing on.

Especially in the military and outdoor industry, where abrasion-resistant and waterproof fabrics and nylon types are required, the robust polyamides are also used for motorbike clothing and work trousers due to their waterproof and hard properties.

Minimum Patch Size – 2.5*2.5cm (25*25mm)

Maximum Patch Size – 50*30cm (500*300mm)

Payment: Paypal or bank transfer

Delivery times : 2 – 4 days (delivery time will always be communicated by me individually before payment)

As the patches are custom-made at the individual request of the customer, any complaints are limited to :

– the difference in size is less than +/- 2mm

– the patch has been damaged by foreign impact (washing, gunshots, sharp objects, chemicals, salt water)

– Camouflage patterns, have an irregular shade/pattern are excluded.

To avoid loss in the post, insured shipping is always paid (Deutsche Post or DHL).

Complaints is when :

– wrong colour/size was supplied

– defective seams

– misprinted text

Patches are used for easy, quick identification, personalisation of equipment and to recognise and distinguish friend from foe. Patches always contain information that is relevant to the wearer or to others. Often patches are used for visualisation and are easy to distinguish and remember thanks to the format and individual design. They come in all shapes and colours – be it a rubber patch or a patch with Velcro, an IR patch or custom patch in the civilian sector. However, they are not a new invention. Badges and patches come from the military sector and have been used there for several centuries.

Since the beginning of military history, officers have worn better equipment and awards on their clothing to distinguish themselves from the rest. In 1810, the British Army used badges to distinguish officer ranks for the first time. Only officers were allowed to wear a badge, and only on their uniform. The patches were made of gold thread and worn on the left breast of the uniform.

A little later, in the American Civil War in 1862, General Philip Kearny Jr ordered his troops to wear a piece of red cloth on their caps so that they could be instantly recognised on the battlefield. The chaotic conditions of a battlefield combined with the weather and similar uniforms made a quick, recognisable solution necessary. The patches were usually sewn by mothers, wives or relatives for the soldiers at the front. From there, the “Kearny Patch” continued to be used and developed until it became today’s tactical patch.

With the industrial revolution, sewing machines and embroidery machines were used to mass produce patches.

During the First World War, tactical patches were first used by the 81st Division Wildcats to boost troop morale. They were worn on the sleeve of the uniform for the first time. General Pershing ordered all divisions to develop and wear an individual patch to create togetherness and a sense of community. From the First World War onwards, patches became a standard part of the uniform.

More patches were produced and worn during the Second World War. They were more detailed and had more information than the patches from the First World War period. What contributed to this was the number of divisions and the different materials used for the patches. The US military even commissioned the Walt Disney Company to develop patches with well-known Disney characters in unique designs and produce 1200 badges to please the soldiers. Five of these designs are still used by divisions today.

At that time, tactical patches were sewn on or fastened with a pin, which took far too long and was not suitable for mass processing. After some time, with mechanisation and the use of new fabrics such as nylon and polyester, Velcro was also discovered for patches. It turned out that Velcro was best suited for tactical patches. Velcro was adaptable in shape, was easy to replace and had a high adhesion. Especially on the battlefield, a patch can be quickly exchanged for a less conspicuous patch.

Patches received a further boost with the NASA campaign and the different patches for each individual mission.

To this day, tactical patches are of great importance and are often personalised and passed on in the military. Many people collect patches too, especially in America.

Unlike Kearny’s red rags on the soldiers’ caps, there are many different types of patches today. They differ in material, attachment, information content and use.

Material & Processing

Woven, embroidered, printed and PVC patches are available.

Laser patches are cut out with a laser, sewn and glued. They are often made of Cordura. A laser cut patch can be used indoors as well as outdoors. It is UV and water resistant. Due to its robustness, laser patches made of Cordura are particularly popular when abrasion, tear and wear resistance are important.

IR patches are used to be read only by IR night vision devices.

A Rubber Patch is made of rubber-like PVC and is therefore particularly durable and weather-resistant. It is also available in an environmentally friendly soft PVC and with a 2D or 3D structure.

A patch with Velcro can be used in many ways. They are usually sewn directly to the Velcro for better durability. They can also be removed at will.

With a custom patch, you can design your laser patch according to its use – shape, colour, material and information content. There are no limits to the possibilities for a unique patch.

Attachment

You can get patches to sew on, with Velcro or glued on.

Information content

Each patch serves to convey various information in a quick and easy-to-understand manner. This includes troop affiliation, rank difference, unit and medical details.

Use

Badges are not only used by the military, such as the Bundeswehr patches. They are also used in civilian and other areas, e.g. the KSK patches, by the Red Cross, by clubs or by the police and fire brigade.

Tactical patches are worn concealed or open in the military. Concealed patches are only visible with night vision equipment or heat light cameras. They are manufactured so that light in the visible spectrum is not reflected. IR reflective patches are visible with night vision devices and FLIR patches are visible with heat light cameras.The concealed patches are used to detect “friends”.

The openly worn patches are easily recognisable in the light and reflect a maximum of white light. They are worn when the wearer does not have to or must not remain concealed, for example on the military base, during operations in cities or in low-light situations.

Besides visibility, the informative content of laser patches plays an important role. Patches must be easily visible, quickly decipherable and easy to understand. The information on the patches is vital in emergency situations. For example, insignia such as name, rank and formation can be seen on various patches. But medical details such as blood group, allergies, etc. are also carried in order to be able to act quickly in an emergency.

Patches are important. Especially in the military, they ensure one’s survival. In other areas, they provide quick information so that you can act correctly and quickly. Find out more on our website and order your individual patches.

Fill out the form and we will get in touch with you